To support the use of such light and thin material, I pushed myself to design the chair for the most minimal shipping impact possible. I realized that notion by segmenting the chair into flat pieces that could be easily assembled by the customer.

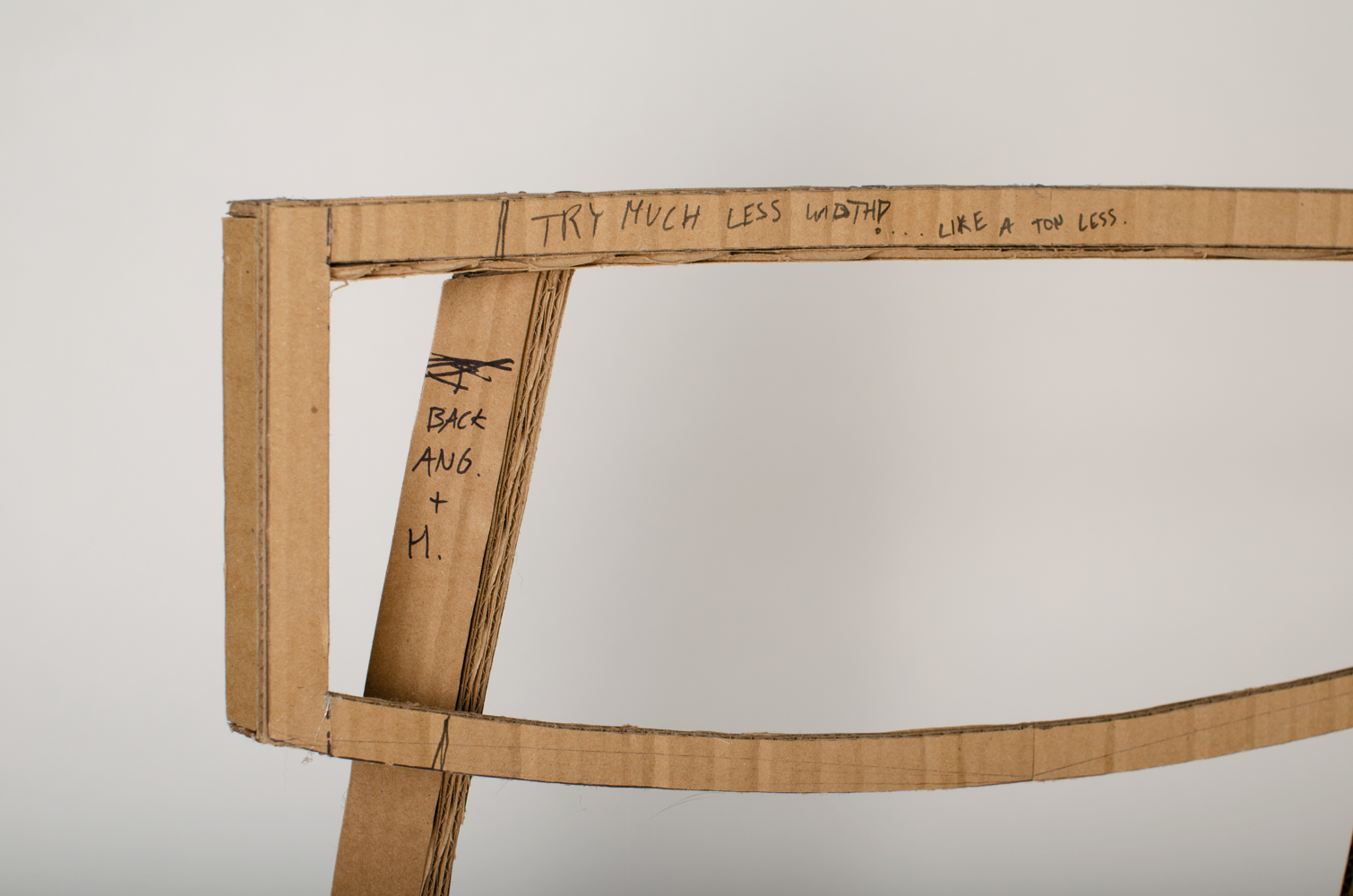

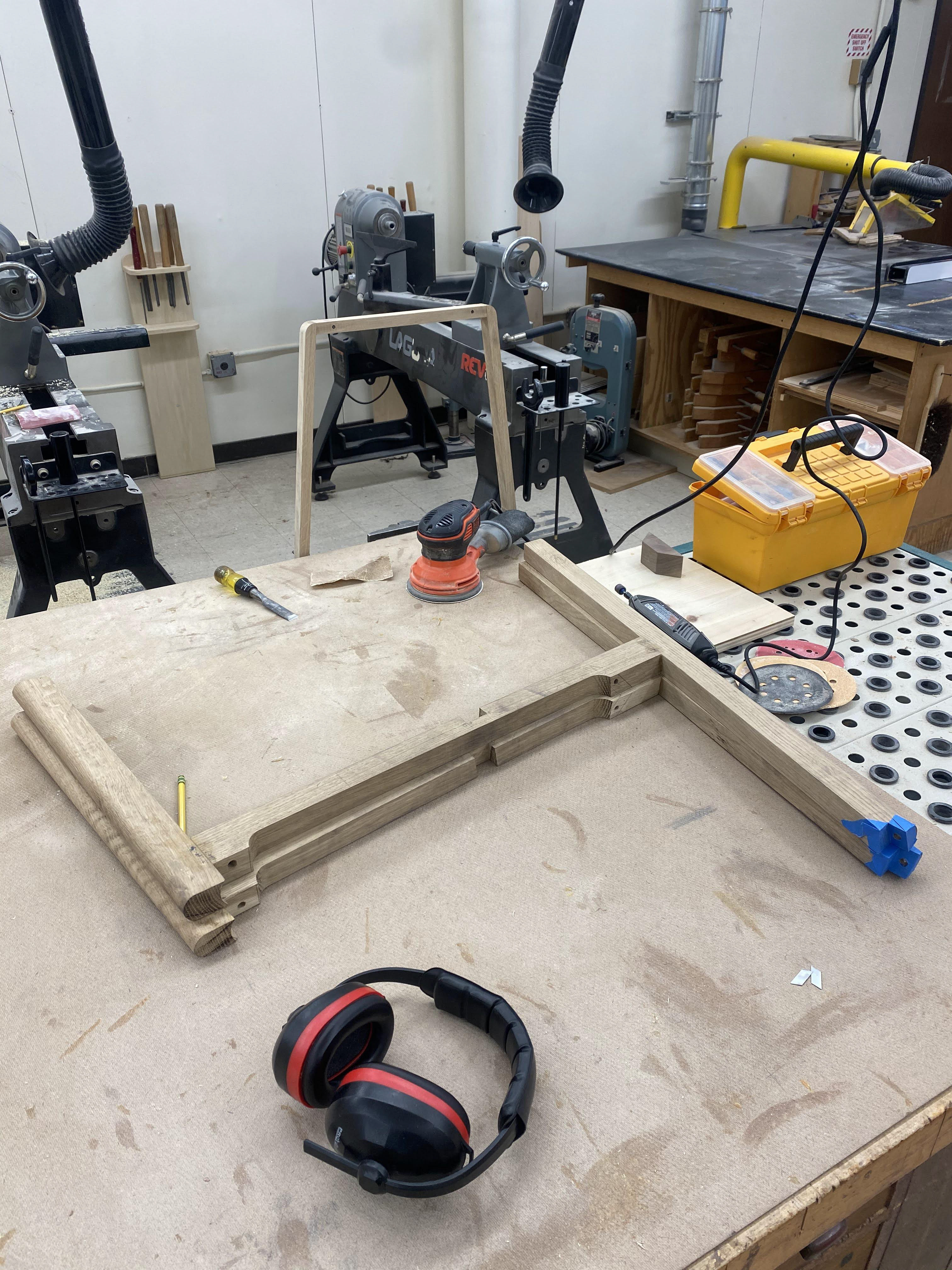

After three rounds of full-scale models in a variety of materials I had refined the proportions and details to a level that I felt was acceptable. I then sourced two planks of American Red Oak and began to cut the final chair.

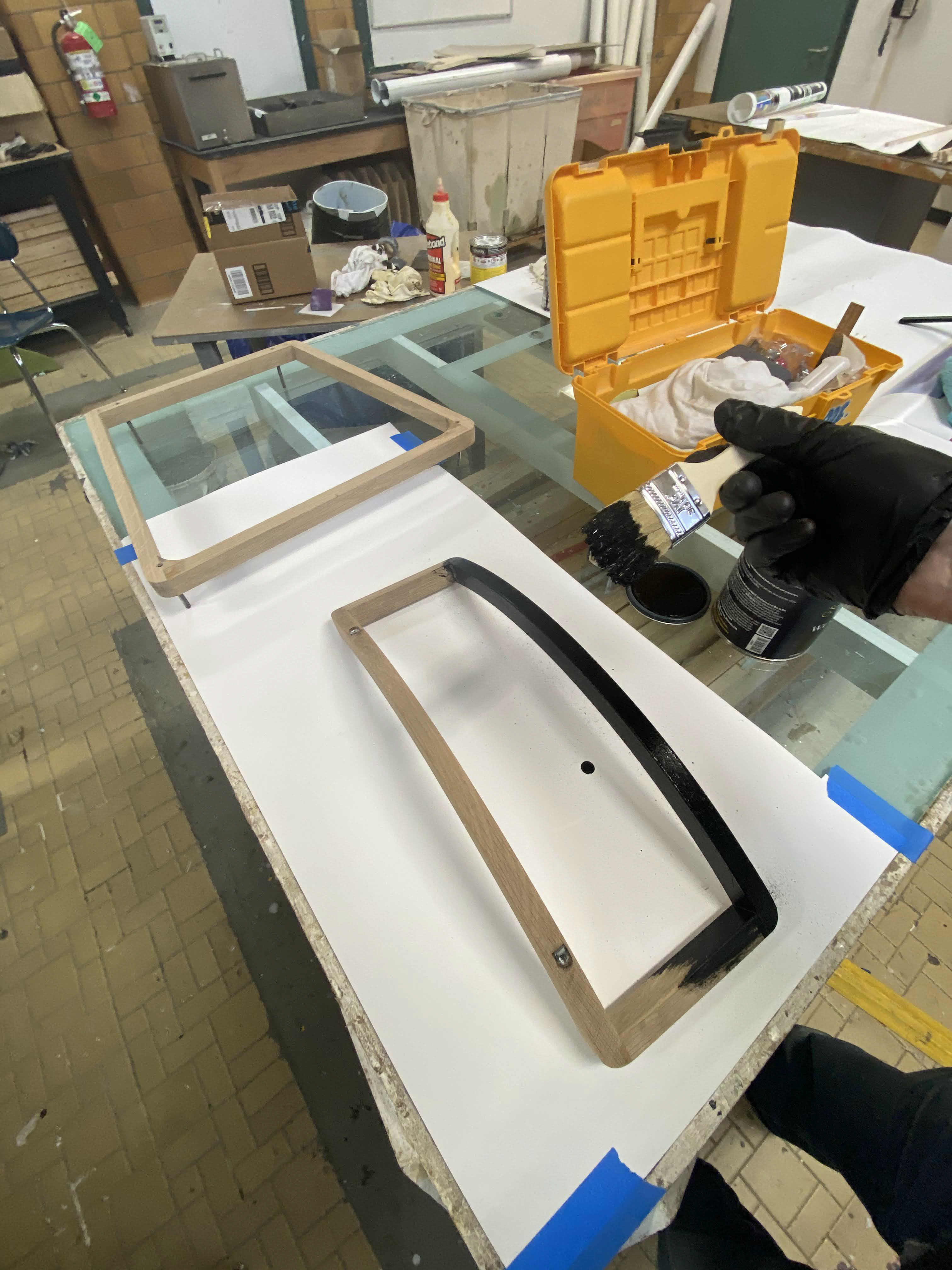

As mentioned, I intended for the Reyes chair to be shipped flat in four pieces and easily assembled by the customer. In order to achieve that, hardware was carefully worked into the chair at integral joints. The main structure of the chair interlocks beautifully without the need for hardware, but the seat pan and back are fixed with threaded inserts and binding screws.

In order to bring out the grain, the final chair was brushed with steel wire before being ebonized with an off-the-shelf product and sealed with wax.